Sustainably clean with rhamnolipids

We go beyond with sustainable biosurfactants

Rhamnolipids are powerful, skin-friendly, and very environmentally compatible. Due to their many positive properties, these biosurfactants can fundamentally transform the markets for personal care products and cleaning agents. Evonik is the first company in the world to produce rhamnolipids on an industrial scale. The new plant in Slovenská Ľupča in Slovakia is the result of years of intensive research.

In 2022, the go-ahead was given for a pioneering project at Evonik’s Slovakian site in Slovenská Ľupča: the construction of a new plant for the production of rhamnolipids. Production began 16 months later, earlier than planned. This makes Evonik the first company in the world to produce rhamnolipids on an industrial scale. It was a milestone.

Rhamnolipids belong to the group of biosurfactants known as glycolipids and are suitable for use as active ingredients in hand dishwashing liquids, shampoos, shower gels, and detergents, for example. Their great advantage over conventional surfactants is that they are 100 percent biodegradable and have a high level of environmental compatibility with microorganisms in bodies of water. They also deliver excellent results in terms of cleaning performance. Moreover, rhamnolipids are very mild to the skin and are gentle on surfaces such as plastic. “The combination of sustainability and high performance is unique,” says David Voigtländer, the head of Research & Development in Evonik’s Care Solutions business unit. "Rhamnolipids are a real game changer in the personal care and cleaning agent markets.”

Rising environmental awareness drives demand for rhamnolipids

Evonik estimates that the market for biosurfactants will grow to around one billion euros by 2032. This growth is being driven by consumers who are assigning increasing importance to sustainable solutions, as well as by regulatory bodies that are setting significantly higher standards for the biodegradability of cleaning substances. “In addition, many manufacturers of personal care products and cleaning agents have committed to greater sustainability,” says Voigtländer. “This will further boost demand.”

Rhamnolipids are produced using biotechnology in a fermentation process developed by Evonik. Other surfactants, including bio-based ones, are produced using chemical processes. “We use European corn sugar as our main raw material,” says Miroslav Havlik, the site manager in Slovenská Ľupča. This means that there is no need for the petroleum and tropical fats that are used in the production of conventional surfactants. In addition, Evonik’s fermentation process consumes less energy than conventional chemical production. “This is also a clear sustainability advantage,” says Havlik.

“The combination of sustainability and high performance is unique. Rhamnolipids are a real game changer”

David Voigtländer, Head of R&D at Care Solutions

Rhamnolipid performance increased step by step

The new plant in Slovenská Ľupča is the result of years of research. In cooperation with the consumer goods manufacturer Unilever, many Evonik experts worked on making rhamnolipids marketable. One of the major initial challenges was to find a bacterial strain that is harmless to humans and the environment and multiplies rapidly under artificially created conditions. After numerous trials, the researchers selected a bacterial strain from the Pseudomonas putida species. Step by step, they managed to increase the bacterium’s performance and finally made it suitable for rhamnolipid production on an industrial scale.

Rhamnolipids are already used in numerous products today. Unilever, for example, has launched a hand dishwashing liquid containing the biosurfactant. In the cosmetics sector, rhamnolipids show their strengths in micellar facial toners, among other things. They are also used in toothpaste. where they have the advantage of a sweet taste. Manufacturers can thus reduce the high cost of flavorings, which usually mask the bitter taste of conventional surfactants in toothpastes.

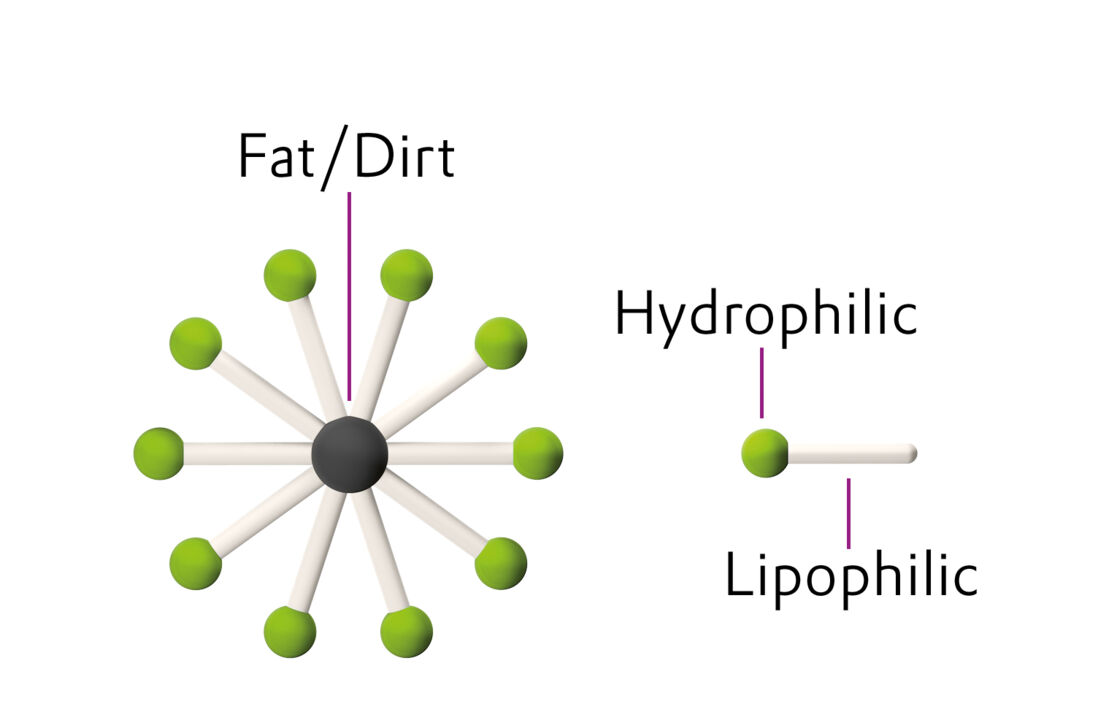

How surfactants work

Surfactant molecules have a hydrophilic (water-loving) and a lipophilic (fat-loving) end. When a soiled surface is washed with water, the dirt particles attract the lipophilic end, while the hydrophilic end points toward the water. These opposing forces loosen up the dirt particles and dissolve them in the water. There the surfactants cluster around the dirt particles by means of their lipophilic ends and enclose the particles in micelles, which are thrown out together with the wastewater.

Evonik is developing additional areas of application for rhamnolipids

Rhamnolipids are suitable not only for personal care products and cleaning agents but also for other areas of application, such as the fields of nutrition, agrochemicals, and coatings. The Evonik product TEGO® Wet Terra, for example, is intended for the coatings industry. As a wetting and dispersing agent for substrates and pigments, it ensures that coatings form a continuous film and that the pigment powder is well dispersed in liquids. Rhamnolipids from Evonik also perform very well here. At the same time, they are gentle in application and thus a healthy option for people who have sensitive skin or allergies, for example.

Together with his team, Stefan Liebig, the laboratory manager at Evonik’s Goldschmidtstraße site in Essen, researches new areas of application for the biosurfactant. For this research, Liebig benefits from rhamnolipids’ unusual chemical structure. “It enables us to give our biosurfactants several product properties that are tailored precisely to the respective area of application and the needs of our customers,” he says. Evonik can therefore offer only just a sustainable molecule but also an entire system solution. Liebig has been involved in the development of rhamnolipids at Evonik for many years. “We are proud to have contributed to our joint success,” he says. “It’s quite a feat to develop a novel biosurfactant and set up a functioning production facility on an industrial scale in only a few years.”

Photos: Andrej Galica / Hugo Bach (5), Staudinger + Franke / Evonik

Infographics: Maximilian Nertinger