3D-Printing

Investment offers 3D printing decision-support system

Evonik Venture Capital has invested in an Israeli software start-up that helps industrial companies adopt 3D printing.

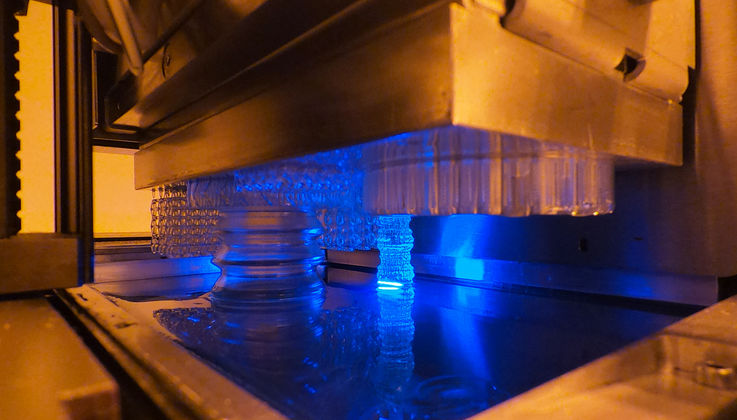

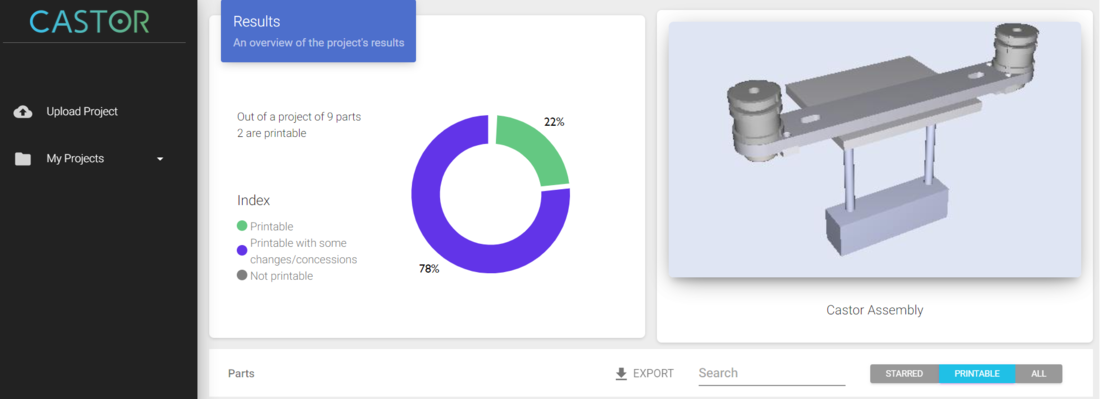

Castor Technologies has developed a software that assesses a part’s printability, the best printing material, cost and lead time. The technology helps manufacturers decide if and how to apply 3D printing to their production processes. The investment enables Evonik to expand beyond selling materials and into services by allowing customers to test printability of their parts.

“Castor occupies an exciting space in the 3D printing market, helping companies overcome the hurdles associated with adopting the technology,” said Bernhard Mohr, head of the company’s venture capital activities. “The investment perfectly complements our existing portfolio of 3D printing activities and is our second investment in Israel, one of the most active start-up ecosystems in the world.”

Helps industrial manufacturers adopt 3D printing

Evonik will contribute its expertise in printing materials and help Castor to establish the software as a platform accessible for all industries. Evonik has more than 20 years expertise in developing and manufacturing 3D printing materials. With Castor’s software, customers will have the opportunity to identify parts that could be printed with materials such as high-performance polymer powders and filaments. Evonik also produces a full range of additives that can modify material properties, for example, improving the flow of the material or making the finished part more robust.

“With the software, broader adoption of 3D printing at a commercial scale becomes possible,” said Thomas Große-Puppendahl, head of the innovation growth field additive manufacturing at Evonik. “That will offer us better insights into customer needs and preferences.”

Castor, based in Tel Aviv, was founded by Omer Blaier, Elad Schiller and David Calderon in 2017. Customers are machinery manufacturers from industries such as automotive, aerospace, medical devices and logistics that have so far relied on traditional production methods such as injection moulding.

Expanding activities beyond materials

The start-up’s software is complementary to computer-aided design (CAD) solutions and customers can analyse their existing CAD files of large assemblies or of many single parts, simultaneously. More specifically, the software performs a comprehensive technical and economic analysis which results in a simple report showing the break-even point for additive manufacturing versus traditional manufacturing methods. This allows manufacturers to decide whether to prefer 3D printing over traditional manufacturing methods and empowers engineers to identify parts which can be defined as the “lower hanging fruits,” leading to cost reduction and time savings.

“Our vision is to be the manufacturers’ gateway to industrial 3D printing,” said Omer Blaier, chief executive officer of Castor. “Evonik’s expertise in 3D printed polymers combined with Castor’s ability to identify unmet needs in material properties is the right combination to improve our customers’ products.”

In addition to Evonik, investors in the current financing round include Chartered Group and Tel-Aviv University’s venture capital fund TAU Ventures.

Evonik Venture Capital helps the company secure access to disruptive technologies and innovative business models as well as supporting digital transformation. To this end, Evonik launched its second venture capital fund with a volume of €150 million at the beginning of 2019, more than doubling the amount under management to €250 million.