Printed Implants

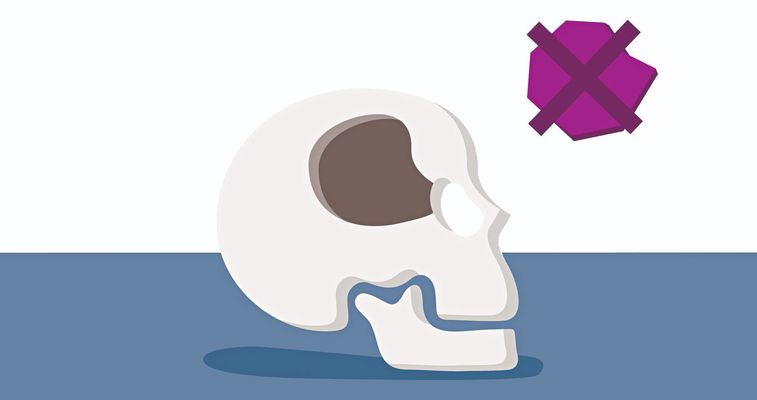

For patients and doctors, 3D-printed implants using Evonik’s high-performance polymer VESTAKEEP® are revolutionary compared with metal: The material is biocompatible and 3D-printing allows customization so that, for example, a plate can be made to fit precisely to the patient’s skull.

Are you going to have an operation? That’s never pleasant, especially not if it’s on a very sensitive part of the body such as the skull.

Until now, surgeons have only been able to insert standard implants. They didn’t fit perfectly and were mostly made of metal.

Until now, surgeons have only been able to insert standard implants. They didn’t fit perfectly and were mostly made of metal.

Its advantage over metal is that it is more readily accepted by the human body. Moreover, the material is almost as elastic as bone.

The 3D-printing startup Meditool, in which Evonik owns a stake, supplies hardware and software that can read images directly from MRT and CT scanners.

As a result, implants made of VESTAKEEP® can be individually printed for every patient—in just a few hours!

What’s more, such implants reduce the likelihood that another operation will be needed to adjust the implant.