VESTOPLAST®

With its VESTOPLAST® amorphous poly-alpha-olefins (APAO) Evonik offers a broad range of co- and terpolymers of ethene, propene and 1-butene as raw materials for various applications in the constructions industry such as window glazing and road constructions.

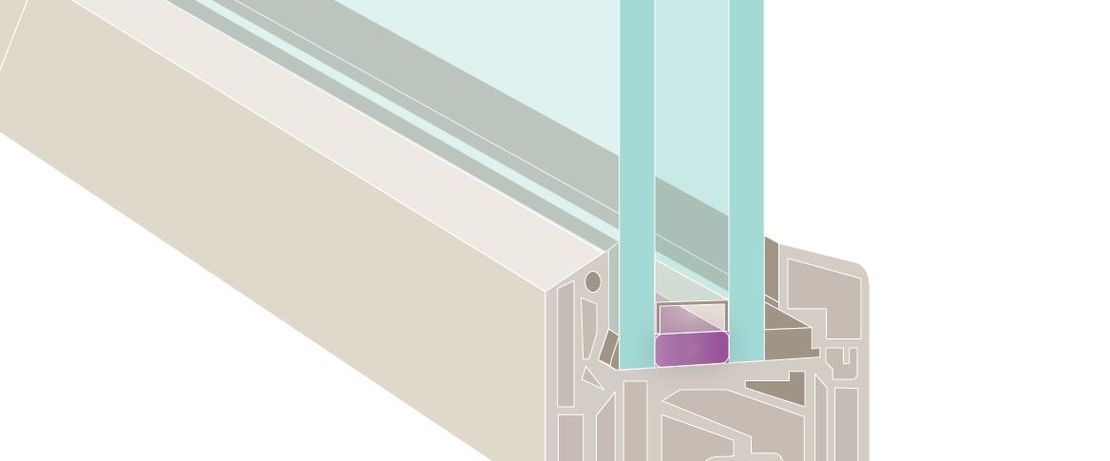

INSULATED GLASS SEALANTS

VESTOPLAST® 206, an amorphous Poly (alpha) olefin, is an ideal solution for primary & secondary window sealants. It exhibits excellent adhesion properties, low water vapor permeability, UV stability and flexibility at low temperatures. With its low water vapor permeability, its flexibility at low temperatures, its good UV stability and good adhesion properties, VESTOPLAST® 206, an amorphous Poly (alpha) olefin, is an ideal solution for primary & secondary window sealants.

Application

Primary and Secondary Window Sealants

Technical Advantages

Primary Sealants

VESTOPLAST 206 as component in butyl-based formulations:

- Excellent adhesion on glass and metal due to reactive bonding

- Improved gas permeability as compared with “Butyls”

- Improved cohesion and elasticity due to cross-linking

Secondary Sealants

- Excellent water barrier due to apolar chemistry

- High weather/chemical resistance

- High filler absorbance capacity (>80% easily)

Roofing / Water proofing

High melting grades from Evonik’s VESTOPLAST range of amorphous poly-alpha-olefins often are component in polymer modified bitumen (PmB) for the production of high-grade membranes for roofing and bridge construction. Beside excellent performance within a broad temperature range, PmBs containing non-reactive thermoplastic VESTOPLAST as a modifier are particularly well suitable for recycling processes, which are becoming more and more important.

Application

Bitumen membranes

Technical Advantages

- Sustainable low and high temperature stability

- Flow resistance at elevated temperatures

- Excellent UV resistance

- High resistance against thermal-oxidative ageing

- Long service time

Bitumen modification

The addition VESTOPLAST® or VESTOWAX® resp. GTL Sarawax to the bituminous binders used in road construction does not only enhance the performance of road surfaces, it also makes construction work easier and safer.

Application

- Modification of bitumen / asphalt

- Colored and white thermoplastic road marking compounds

Technical Advantages

- Improvement of stability particularly of asphalts exposed to high weight-loading (airport runways, container terminals, industrial sites)

- Quick and simple incorporation directly on site

- Softening and glass transition temperature reduction of thermoplastic road markings