Sustainable Gas Economy

The green hydrogen revolution starts now

Evonik is committed to driving the transition of today’s conventional energy supply to a sustainable gas economy of tomorrow – based on green hydrogen as one of the main cornerstones. Evonik works in many areas to help make this vision a reality.

Hydrogen is the most common chemical in the universe. It is an important building block for chemical production as well as a significant source of energy. Together with our partners along the global value chain for renewable technologies, Evonik is committed to drive the transition of today’s conventional energy supply to a sustainable gas economy of tomorrow – based on green hydrogen as one of the main cornerstones. That's why we are already working in many areas to help make this vision a reality.

To date, the main user of hydrogen has been the chemical industry, which needs it for various synthesis processes. More than half of the globally produced hydrogen is processed into ammonia, primarily for fertilizer. Refineries also need huge amounts of hydrogen, for example to crack and desulfurize petroleum products. This overview shows the economic potential of this gas — from its production and processing to its use.

GREEN IS THE COLOR OF HOPE

In today’s hydrogen production, steam reformers cover more than 95 percent of the worldwide demand for hydrogen. They use heat, pressure, and catalysts to produce hydrogen from fossil sources such as natural gas. This process generates about ten tons of carbon dioxide (CO2) per ton of hydrogen. According to the International Energy Agency (IEA), in recent years hydrogen production has generated about 830 million tons of CO2 emissions worldwide per year. That’s more than the emissions of the UK, France, and the Czech Republic taken together. This is not a good balance sheet for hydrogen, the beacon of hope for advocates of an energy transition.

Hydrogen can be produced directly from water by means of electrolysis. The principle is simple and well known: A voltage applied between two electrodes splits water into its chemical components, oxygen and hydrogen. In a fuel cell, this process is reversed: Hydrogen and oxygen from the air react without combustion to form water. The reaction generates an electric current and some waste heat. Within this cycle, hydrogen is the storage medium for electrical energy. This potentially climate-neutral cycle, which is expected to spur the energy transition, is now attracting large amounts of attention and ¬capital.

According to the IEA, currently less than 0.1 percent of the hydrogen produced around the world comes from electrolysis. The expansion of these capacities has begun. Since 2000, the IEA’s database has registered more than 300 hydrogen projects that are either under construction or in the planning stage. Most of them are in Germany. Recently, however, new electrolysis facilities have on average had a capacity of just one megawatt.

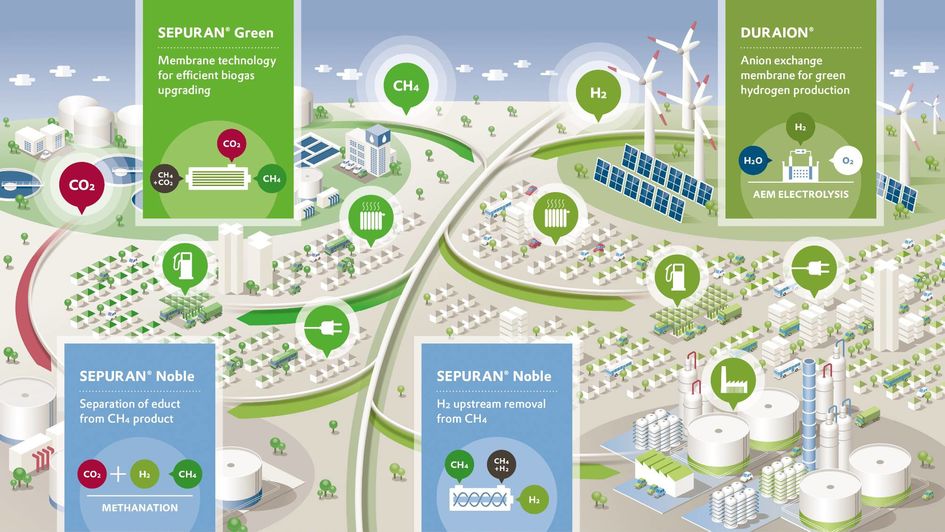

At the Marl Chemical Park, Evonik is developing a novel anion-conducting membrane to produce green hydrogen at low cost (click here for more information). It is the heart of the AEM water electrolysis process. Electrolysis with anion-conducting membranes has clear advantages over other electrolytic processes such as classical liquid electrolysis with diaphragm (AEL) or the newer PEM electrolysis (short for proton exchange membrane) under acidic conditions. AEM electrolysis promises lower investment costs, because operation under alkaline conditions enables precious metal-free and thus significantly less expensive materials for the cells. In addition, it is characterized by high current density, very good efficiency and high flexibility in power feed-in.

Green hydrogen for storage of renewable energy

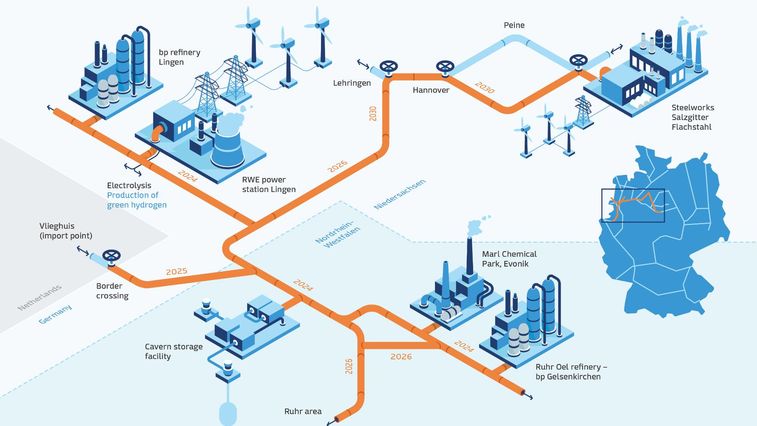

One of the biggest challenges today for renewable energies to be delivered to the consumers is the fact that renewable energies are not always at a place where they are needed the most because the concentration of industries or individuals is elsewhere. “The idea is to convert that energy at the point of source into green hydrogen and transport it to the consumers. For this, we will need an infrastructure of pipelines”, says Caroline Justet, Business Growth Executive at Strohm B.V. Evonik’s polyamide 12 is the high-performance material of choice for flexible pipelines which can be used for green hydrogen transportation. How it works shows the GET H2 Nukleus project. Germany’s first publicly accessible hydrogen network is due to supply increasing quantities of green hydrogen to industrial companies in Lower Saxony and North Rhine-Westphalia from late 2024 onwards.

Until a new pipes network for green hydrogen is installed, existing pipeline networks could be used to efficiently transport green hydrogen over long distances and deliver it to end points along this infrastructure. There it could be fed into industrial applications or provide a source of energy. For this to happen, however, the hydrogen must be efficiently separated from the natural gas blend at the point of extraction. Linde and Evonik Industries already offer a fully integrated, holistic solution (click here for more information) that brings together various technologies for hydrogen separation. This solution combines pressure swing adsorption (PSA), a technology in which Linde has decades of experience, with Evonik’s hollow-fibre membrane technology to deliver hydrogen at purity rates of up to 99.9999 percent. “What we need now is smart transformational technology”, points out Tobias Keller, Head of Adsorbtion & Membrane Plants at Linde Engineering.

ENABLING SUSTAINABLE GAS ECONOMY

Evonik is a global membrane technology leader for the gas industry. Following the Sustainable Development Goals of the United Nations, Sustainability is the key growth driver and the cornerstone of our product portfolio, investments and innovation management and thus an integral part of Evonik’s strategy. With the innovative gas separation SEPURAN®, PURAMEM® as well as the advanced ion-conducting DURAION® membrane technologies, the specialty chemicals company makes the global transition of conventional energy supply to a sustainable gas economy of tomorrow possible. “We believe in a fully renewable energy mix of the future with biogas and green hydrogen and their synthesis products as the main energy streams. That's why we are already working to expand our product portfolio in line with sustainable market development”, says Dr. Goetz Baumgarten, Head of the Membranes Innovation Growth Field at Evonik.

By 2030, Evonik aims to invest more than €3 billion in Next Generation Solutions - products with superior sustainability benefits. That is around 80 percent of annual growth investments. In the same period, a further €700 million will be invested in Next Generation Technologies, i.e., the optimization of production processes and infrastructure to avoid CO2 emissions.

Janusz Berger

Head of Market Communications Innovation Growth Fields High Performance Polymers

E-Mail: janusz.berger@evonik.com

Remark: Siemens Energy is a trademark licensed by Siemens AG