The history of disinfection

The journey of peroxides

Today, peroxides are considered indispensable disinfecting agents. But the road to mainstream acceptance of that insight was rocky. Evonik and its predecessors have been there since the beginning.

In 1818, French chemist Jacques Thénard became the first to successfully produce hydrogen peroxide by reacting barium peroxide with nitric acid. Shortly after hydrogen peroxide had been made in the lab, peracetic acid was discovered as well.

Production of these materials was difficult given the resources available at the time, however: even the tiniest traces of heavy metals or organic residues can produce violent breakdown reactions – a frequent cause of laboratory accidents.

For this reason, the use of “oxygenated water”, as it was called, was limited to just a few specialized applications in the early 19th century. It worked as a brightener, for instance, for old paintings in which the white lead in the paints had blackened following reaction with hydrogen sulfide.

Hydrogen peroxide becomes a disinfectant

In medicine, hydrogen peroxide was initially used only as an irritant for external application. In 1858, English physician Benjamin Ward Richardson published a paper in the journal The Lancet describing how hydrogen peroxide could be used for eliminating foul odors and proposed using it as a disinfectant. A few years later, a weak solution of hydrogen peroxide was introduced under the brand name Sanitas and marketed for precisely that purpose. The product was to be used for canning and even for cleaning public restrooms.

In 1894, German chemist Richard Wolffenstein became the first to obtain pure hydrogen peroxide via vacuum distillation.

An electrochemical method for producing hydrogen peroxide was patented in 1906 by Otto Margulies, the founder of the company Österreichische Chemische Werke (ÖCW). Roughly four years later, in January 1910, the world’s first electrolytic hydrogen peroxide factory began operations. The new trailblazing method marked the first time that highly concentrated (30 %) hydrogen peroxide could be manufactured on an industrial scale.

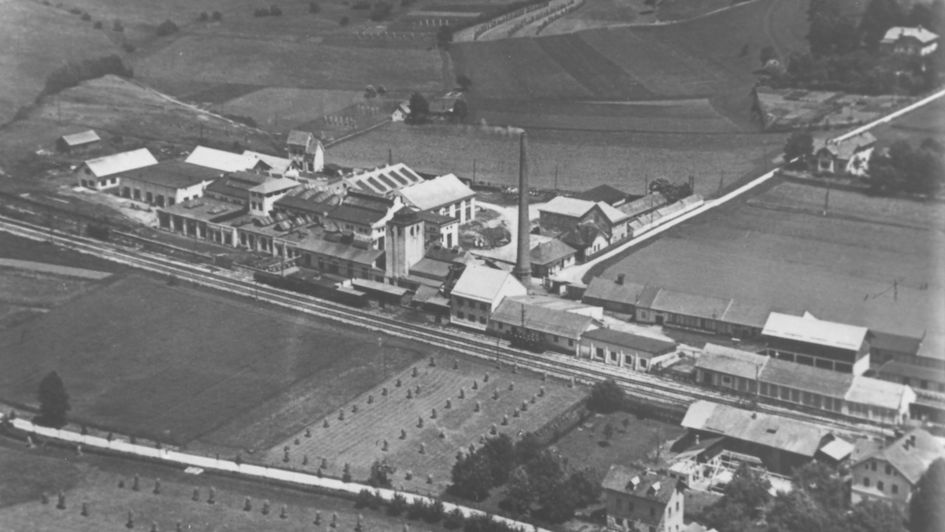

Aerial image of the Degussa production site at Weißenstein (Carinthia, Austria), 1939.

Disassembling of the peroxide production site at Rheinfelden, 1947.

Distillation of hydrogen peroxide at Rheinfelden, 1961.

Hydrogen peroxide production site at Antwerp (Belgium), 1994. Production at this site was launched in 1970.

We started production of hydrogen peroxide at Barra do Riacho in the State of Espírito Santo (Brasil) in 1998. Ten years later Evonik increased its capacity to 70,000 tons per year. The image was taken in 2004.

In 1987, we launched production of H2O2 at our plant in Mobile, Alabama (USA) using the anthraquinone process. Four years later we expanded production with a second facility. The image was taken in 2007.

Their improved availability launched peroxides on an extraordinarily successful path. While early attempts to use hydrogen peroxide to disinfect wounds did not yield satisfying results, the compound was considered ideal for preserving milk and water (1913) and hot chocolate powder (1927).

The first industrial method for manufacturing peracetic acid was developed around 1930. The commercial breakthrough for the highly reactive substance came decades later, however: it was not until the 1960s that plastic containers made shipping and storage easier and safer.

New production processes, new applications

Starting in 1965, the former Degussa company switched over to a new hydrogen peroxide production process. The material would no longer be synthesized electrolytically but would instead be produced in an organic medium. The anthraquinone process, as it was known, became the global standard.

Experiments began in the 1970s on the use of hydrogen peroxide baths as the first non-thermal method for disinfecting contact lenses. Finally, the US Food and Drug Administration approved the first of these solutions in 1983. The first patent for a hydrogen-peroxide-based tooth-whitening gel was registered in 1989.

In response to the pandemic spread of SARS-CoV-2, the World Health Organization published recommendations in 2020 for manufacturing alcohol-based hand sanitizers, advising the addition of hydrogen peroxide to prevent microbial growth in the solution.

During this time, peracetic acid has proven effective in disinfecting wipes used for cleaning rooms and transit vehicles. Its effects are fast and reliable, and because it breaks down into water and CO2 after use, it is also exceptionally safe for the environment.