Chemical Recycling

|

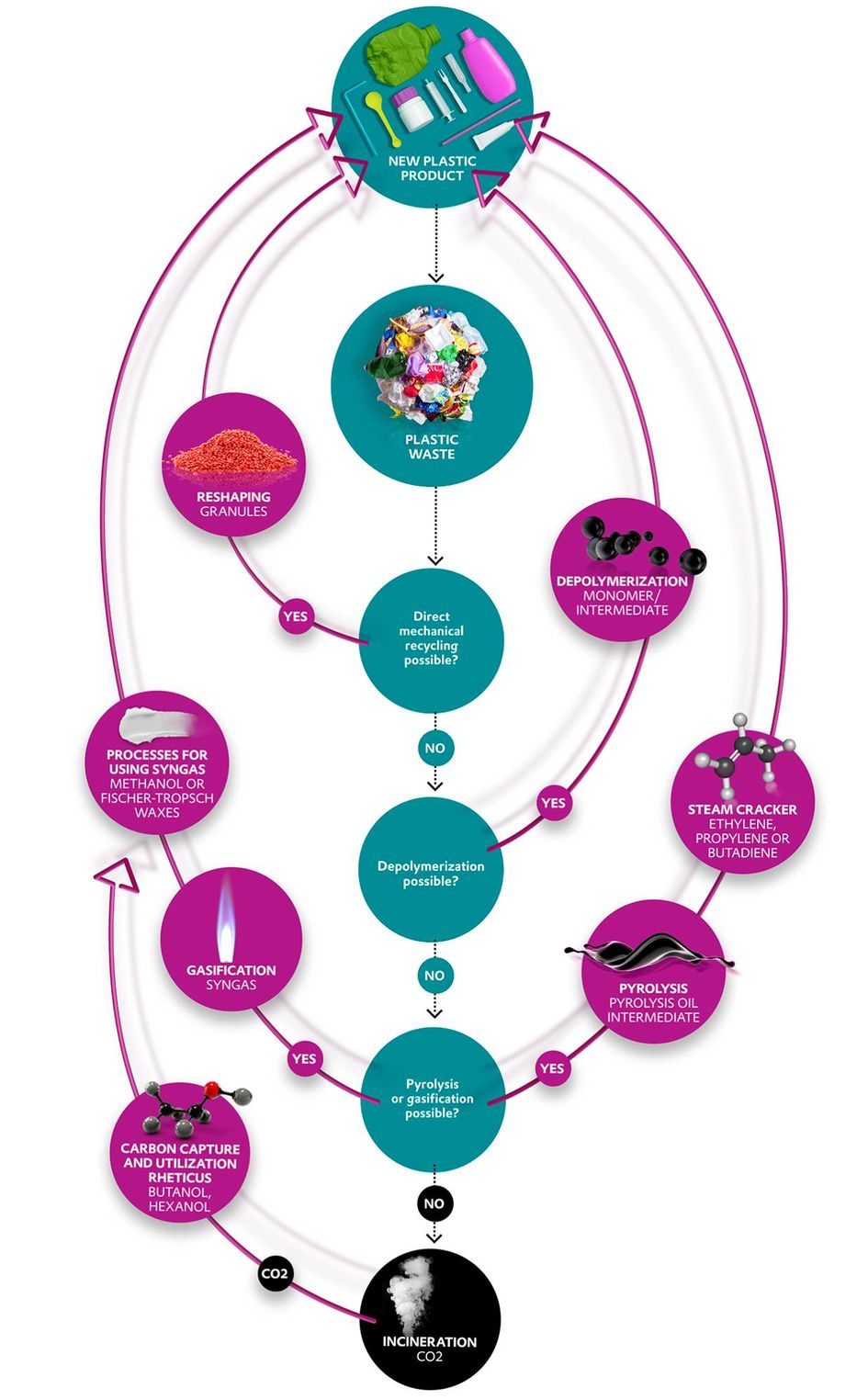

MECHANICAL RECYCLING IS THE FIRST DIVISION OF RECYCLING TECHNOLOGY: a cycle for single-source thermoplastics. However, there is also a lot of plastic waste that is not good enough to enter the first division cycle – in a linear economy, it faces incineration or is put in a landfill. This is where chemical recycling comes into play – the second division, so to speak: a cycle for hard to recycle raw materials, especially mixed waste, highly contaminated plastics, and even thermosetting materials that cannot be melted down. However, as these occur in huge quantities, it is all the more important to continuously expand this second division. In chemical recycling, the waste materials are broken down into their basic building blocks, known as monomers, using catalysts. Evonik is working on a platform technology for cost-efficient processes with an optimized life cycle assessment. The aim of the Evonik researchers is to use newly developed, scalable processes to make large new material flows recyclable in the first place. |

|

Some of the Evonik solutions have long since left the lab and have proven their effectiveness on a pilot scale. For example, in PET methanolysis with sodium methylate as a catalyst or in polyurethane recycling, for which we have developed tailor-made catalysts. Evonik is also heavily involved in converting mixed plastic residues into pyrolysis oils: our adsorbents and HPC catalysts allow the separation of impurities and contamination during production, while our additives stabilize the finished pyrolysis oil and minimize crystallization. The pyrolysis oil is thus prepared to replace petroleum-based Naphtha in the petrochemical process. The result is e.g. ethylene or propylene for the production of polyethylene or polypropylene, which does not differ from the fossil variant but is free of petroleum. Many millions of tons of waste are still waiting to be converted into valuable materials – the complementary technology team of mechanical recycling and chemical recycling has the potential to do this. At least with the right partner. If you would like to be part of our pioneering work, our team will be happy to hear from you. |