Mechanical Recycling

Enabling the reuse of single-source plastics. ... MORE

A brain that has already learned a lot creates new cross-connections more quickly and becomes smarter as a result. The same applies to our circularity expertise: the more we know, the more we learn. And we already know a lot!

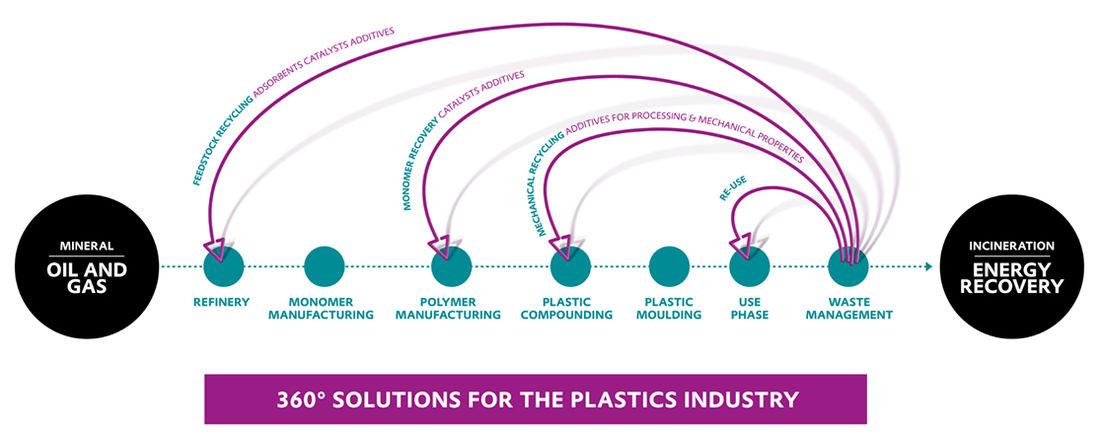

Evonik has been manufacturing specialties for the plastics industry for decades: we make our customers’ products more robust, more efficient, of higher quality, and, above all, more durable. After all, what stays in use for a long time creates less waste.

We are now using the knowledge gained over decades about markets, products, and processes to establish efficient plastics cycles. To this end, we operate several application laboratories in Germany with associated technical centers. In Essen, we are investigating the possibilities of mechanical recycling with our own extruders and our own film machines. And always with the aim of enabling recyclates without any loss of quality. At the same time, we are improving chemical recycling in Marl and Hanau. For example, with new catalysts and processes that enable our customers to break down polyurethanes or polyethylene into their basic chemical building blocks, or which can be used to separate impurities from chemical recyclates.

Evonik is also a pioneer in enabling chemically recycled raw materials. Our production facilities in Antwerp (Belgium) and in Marl (Germany) are certified in accordance with the ISCC PLUS standard for mass balancing. As with green electricity, renewable and fossil resources are brought together in a cycle and mass balance helps to follow the substitution with renewables. And that’s without compromising on quality which enables our customers and partners to produce more environmentally friendly products without having to change their production.

Mechanical and chemical recycling complement each other like two good team partners: one can do what the other cannot.

Evonik already offers key components for both technologies. But we cannot stop there: we, the research companies of the industry, need to continue to invest in order to meet the needs of the rapidly growing market.

Clever and integrable ideas are necessary to make way for a closed plastic cycle. From us. From OEMs. From recyclers. And, of course, from you. Circularity is a team sport: Join our “Sustainability team” – we are looking forward to hearing from you!