Mechanical Recycling

|

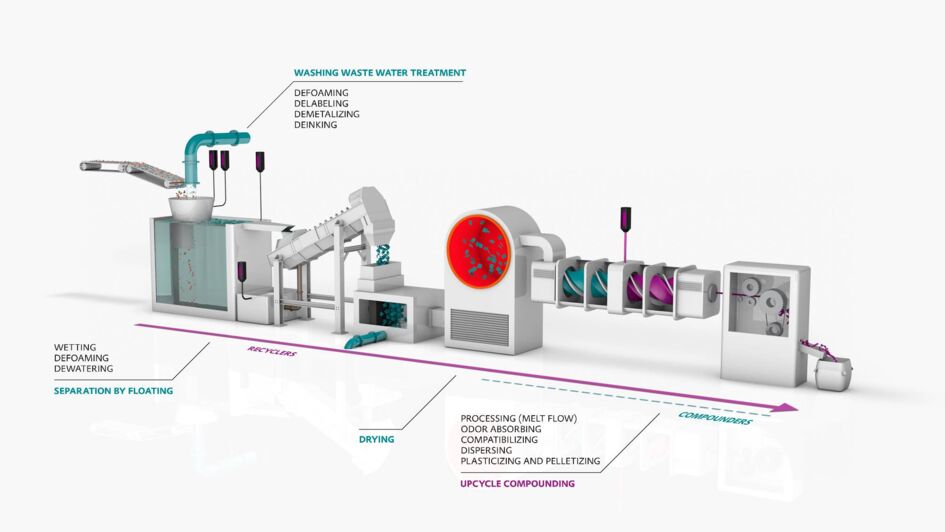

THE LAST THING A THERMOPLASTIC SHOULD SEE AT THE END OF ITS HOPEFULLY LONG LIFE IS A SHREDDER. After all, mechanical recycling is the most efficient way to recycle plastic in accordance with the current state of art. However, far too many plastics come to the end of their lives much too quickly: around 370 million metric tons of plastic produced worldwide every year, almost 70% is single-use plastic. It goes without saying that we need to reduce this number. However, it is also clear that we need to increase the recycling rate. And that is where specialty chemicals come into play as part of the solution. The plastic goes through various stages in the recycling process. At each of these stages, Evonik products are used to increase cost-effectiveness, improve the quality of the recyclates, and increase yield. |

|

Do you want evidence? To increase efficiency during de-inking and delabeling, we develop tailor-made surfactant formulas for detergent liquors. Together with our defoamers, our surfactants ensure that the detergent liquor gets between surfaces better – for example, to cleanly separate foils and aluminum. During subsequent drying, our additives help to shorten the drying time and save energy. And finally, in the finished recyclate, our odor absorbers prevent unpleasant odors from being emitted by locking volatile molecules in the material. These examples show that Evonik makes a fundamental contribution to a more economical and high-quality result at every step of the process. And if that wasn’t enough proof for you, take a look at our case studies. |