Rubber Recycling

|

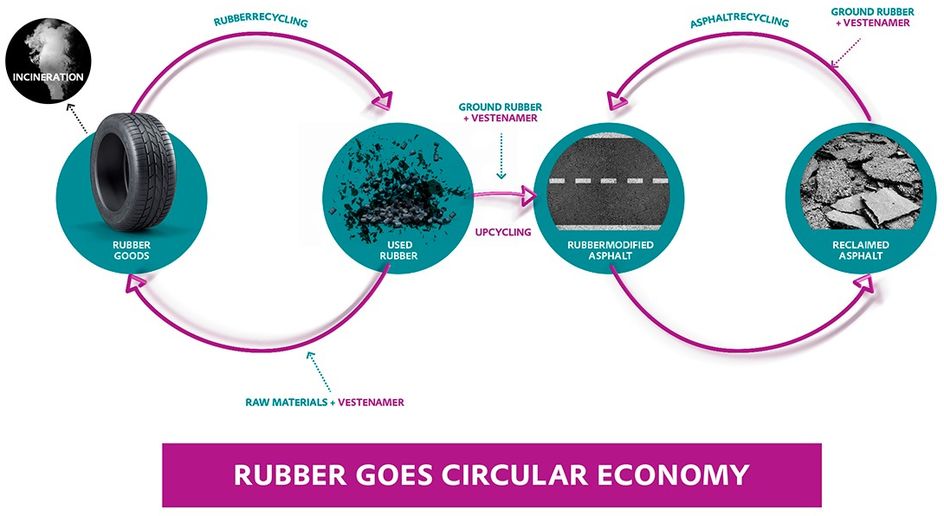

AROUND THE GLOBE, 19.3 MILLION TONS OF OLD TIRES ARE PRODUCED EVERY YEAR. That’s roughly equivalent to the weight of the world’s largest passenger aircraft – every week! In view of this amount, rubber recycling should be a matter of course. But it’s not! The majority of used tires are still burned, for example in cement plants. Rubber has the same two open options as plastic does: mechanical and chemical recycling. However, they also face the same challenges: the recycling rate will only increase when rubber recyclates offer attractive quality for further processing. |

|

Evonik has had additives on the market for years now that improve both the cost-effectiveness of mechanical rubber recycling and the quality of the products. Even small quantities of our quality boosters increase the compatibility of the mixture in asphalt or rubber applications. The result is stable quality with a long shelf life and high level of physical resilience. In addition, we use our additives to make lower quality rubber recyclable in the first place, thereby further reducing the proportion of waste materials. This means that the successes are in fact there. But the whole thing is still going too slowly for us! We want to use our advanced knowledge give many more old tires a new lease of life. So make us your cooperative partner in a market that is set to grow over the next few years. A market that has to grow! |