Supply Chain Management

The aim of our procurement organization is to guarantee long-term reliability of supply for the production of Evonik products and to secure competitive advantages for our operating businesses. Alongside economic requirements, our procurement strategy takes account of criteria such as health, quality, safety, social factors, and environmental protection.

PROCUREMENT MANAGEMENT

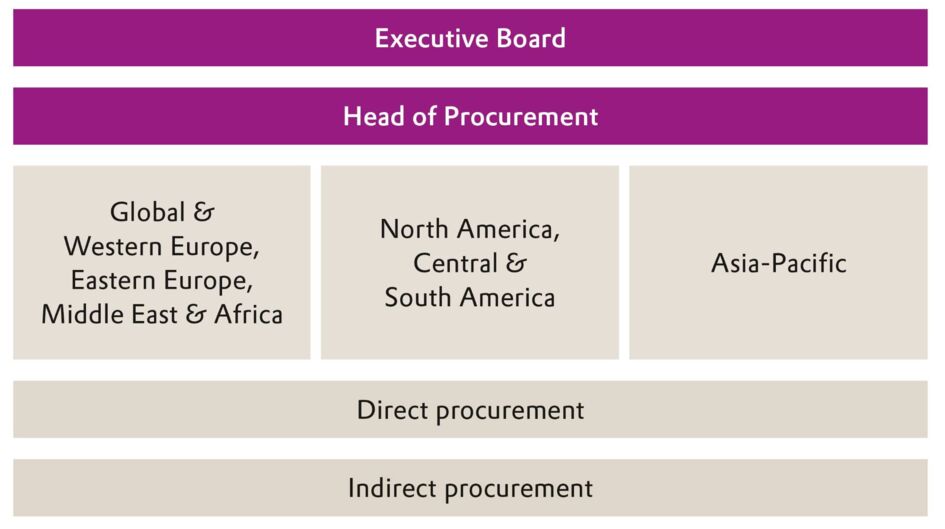

Procurement is organized globally at Evonik and comprises direct procurement (raw materials, logistics, and packaging) and indirect procurement (general and technical goods and services). Both are subdivided into strategic and operational procurement activities. Global procurement is managed from Germany, with the support of regional units in Asia and North and South America.

PROCUREMENT MANAGEMENT at Evonik

QUALIFICATION AND EVALUATION OF SUPPLIERS

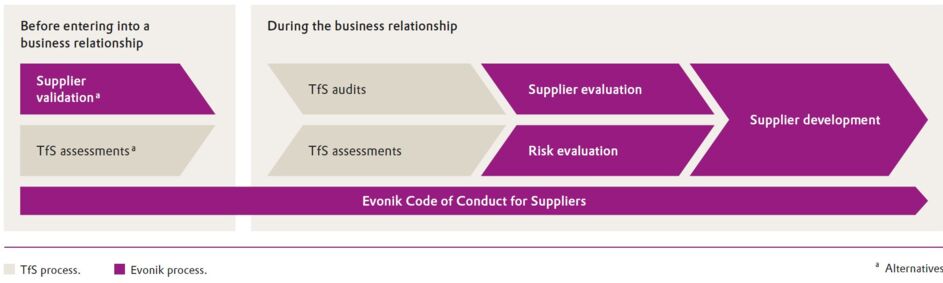

The qualification and evaluation of our suppliers is an integral part of our sustainable supply chain management. As part of the qualification of new suppliers, compliance with our Supplier Code of Conduct is checked. When evaluating suppliers, we pay particular attention to our strategic suppliers as well as suppliers of strategic raw materials. Strategic suppliers or raw materials are defined as those that have been identified in consultation with the operating units due to their particular significance for the success of the business. This can refer to key raw materials or single-source situations, for example. We are consistently working on the expansion of strategic supplier relationships as well as on the qualification of new suppliers. In addition to our Supplier Code of Conduct, we pursue an approach that:

includes its own assessments and audits, as well as the verification of suppliers as part of the Together for Sustainability (TfS) initiative.

We expect our suppliers to share our principles and to act correctly in all respects, i.e. to live up to their responsibility towards their employees, their business partners, society and the environment. Within the framework of a fair mutual understanding of business, Evonik always strives to settle outstanding invoices within the agreed payment terms. Around 90 percent of the invoice values are paid within 60 days. The establishment of a supply relationship begins with the qualification. To this end, we use a qualification process based on the values set out in our Supplier Code of Conduct. In addition to quality, environmental protection, safety, health and energy management, the review of possible risk factors also includes the topics of anti-corruption, cyber security, labour and social standards (right to freedom of association and collective bargaining) as well as human rights (forced, compulsory or child labour), conflict minerals and responsibility in the supply chain. All information is recorded online and evaluated in a qualification matrix. During the initial inspection, a country and not a separate permanent establishment assessment takes place. The values and expectations of our Supplier Code of Conduct are communicated to all suppliers via the General Terms and Conditions of Purchase. In 2023, we reviewed 1,440 suppliers as new suppliers. This corresponds to a share of more than 85.2 percent of new suppliers. Successfully completed TfS assessments can also be used as proof of qualification. Overall, supplier evaluation follows an approach to capture and quantify risk factors in order to address them.

In 2023, we reviewed a total of 1,548 suppliers. This is the result of the audits, assessments, and supplier qualifications carried out by TfS and directly by Evonik.

We apply the same care to the evaluation of existing supplier relationships. In addition to the annual evaluation of all significant supplier relationships, a detailed review of strategic suppliers takes place.

Supplier validation and evaluation

RESPONSIBILITY IN THE SUPPLY CHAIN

In the year under review, we further improved our processes for evaluating and qualifying suppliers. This includes, in particular, the risk assessment of suppliers with regard to human rights requirements. In addition, the commodity risk analysis has been refined by taking a closer look at regional and geopolitical dependencies than before. This allows us to react more quickly in a volatile environment. In the course of the validated SBTi targets, communication with our suppliers was further expanded and the great importance of product carbon footprints for a sustainable business relationship was pointed out. In addition, we have established product carbon footprints as a possible decision-making criterion in the purchasing process and included them in the award decision. This goes hand in hand with transparent communication to our significant suppliers that we expect to provide data regarding the CO2 footprint (product carbon footprint) of their products by the end of 2025 at the latest. In terms of our climate targets, we have taken the next important step based on the guideline for the uniform calculation of product carbon footprints in the TfS initiative published in October 2022.